Site-finished flooring has, for the longest time, been a staple in high-end projects for years. The smooth-sanded look and the endless possibilities with on-site finishing, in the past, has been highly sought after to represent the best in quality installation and style. However, with the continued custom advancements in manufacturing, as well as the standard lead time for projects continuously shortening; prefinished flooring has become more and more prevalent throughout projects across the globe. Color, texture, species, etc. are the decision most commonly discussed first. Although, another often overlooked, and rarely considered specification detail to your wood floor is what to do to the edge of each plank. Each edge treatment has advantages and disadvantages both in maintenance and durability as well as in appearance. Site-finished flooring has, for the longest time, been a staple in high-end projects for years. The smooth-sanded look and the endless possibilities with on-site finishing, in the past, has been highly sought after to represent the best in quality installation and style. However, with the continued custom advancements in manufacturing, as well as the standard lead time for projects continuously shortening; prefinished flooring has become more and more prevalent throughout projects across the globe. Color, texture, species, etc. are the decision most commonly discussed first. Although, another often overlooked, and rarely considered specification detail to your wood floor is what to do to the edge of each plank. Each edge treatment has advantages and disadvantages both in maintenance and durability as well as in appearance.

What Styles of Edge Treatments Are There?

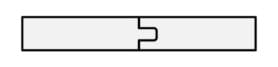

Squared Edge

The seamless edge of square edge flooring is one that closest resembles site-finished flooring. Square edges also blend well with other flooring options and help direct focus on the overall look of the floor. This is also considered by many to be the flooring easiest to maintain as there is no dipped edge in which to collect dirt.

Beveled Edge

Beveled edge flooring is recognizable by the distinct grooves that are added to the edges of planks. A Urethane finish works best on this type of flooring as it allows for dirt to be easily swept or vacuumed away. Beveled edges also can be forgiving when being installed over irregular subfloors or with uneven plank heights.

Micro-Beveled Edge

A Micro-beveled edge has a similar, but less severe, groove than that of the standard beveled edge. This is the most popular edge treatment used on both residential and commercial project by prefinished flooring manufacturers. Each board specifically has a mini-bevel for a similar effect to the standard bevel of masking any minor irregularities.

Cambered Edge

Cambered edge is a slightly more pronounced edge treatment than a square edge. It is widely thought to help emphasize the texture and detail of each plank. Multiple finishes are acceptable for this type of edge treatment as dirt buildup is not as high of a concern. A much more uniform and seamless appearance is obtained through the proper installation of this style of the plank.

Pillowed Edge

The pillowed edge is a more rounded bevel to the edge treatment. This specific style of edge treatment is most commonly seen on Antique wood flooring which assists in maintaining that traditional and rustic characteristic of the wood.

Scraped Edge

A scraped edge is a type of edge treatment that emphasizes plank individuality. This treatment is, in most cases, used to mimic the look of a heavily hand-scraped or double hand-scraped flooring plank.

Whether you’re looking for a more traditional, rustic, modern, or casual look to your wood flooring on your next project, there is always an edge treatment that best fits the aesthetic you’re after. However, when selecting an edge treatment for your wood flooring specification, it’s best to remember to contact your local wood flooring specialist in order to confirm this is the correct style for your maintenance, durability, and finish option needs.