From Forest to Floor: Wood’s Long Journey

When you picture wood floors in historic buildings, you may see expanses of polished floors accented with decorative rugs, but this look wasn’t common until the early 19th century. Wooden floors in Colonial America were made from wide, thick planks cut from old-growth trees. This tight-grained heartwood was extremely durable but very humble in appearance.

After World War II, carpeting became more affordable and the use of wood declined. But in the 1990s, wood flooring experienced a resurgence when less expensive, engineered wood was introduced. Designers and consumers began to rediscover the many benefits of hardwood floors.

But have you ever wondered how that wood made its way from the forest to your floor?

Raw Materials

The trees harvested to produce lumber are classified as either hardwoods or softwoods. Although many hardwoods are hard, and many softwoods are soft, that’s not actually what defines them. Most hardwood trees have leaves which they shed in the winter. Hardwoods include oaks, maples, walnuts, cherries, and birches, but also balsa, one of the softest and lightest of all the woods.

Softwood trees don’t have leaves but instead needles that they keep all year. Softwoods include pines, firs, hemlocks, spruces, redwoods, and evergreens.

Hardwoods, which are generally more expensive than softwoods, are used for flooring, cabinetry, paneling, doors, trim work, and furniture. Softwoods are used for wall studs, joists, planks, rafters, beams, stringers, posts, decking, sheathing, subflooring, and concrete forms.

In the United States, most trees used for lumber are grown in managed forests owned by a lumber company or leased from the government. After trees have reached an appropriate size, they are cut down and transported to a mill where they are cut into various sizes. The following is a typical sequence of operations for processing trees into lumber.

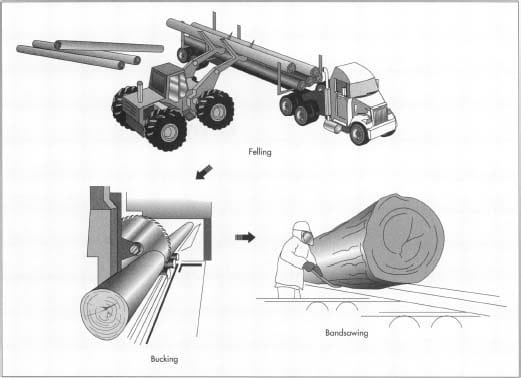

Felling

A forestry worker will determine when and which trees should be cut down, depending on their economic maturity. Based on their species, trees may be anywhere from 40 to 150 years old before they stop growing rapidly, reach their economically ‘mature’ stage, and are ready to be harvested. Felling usually takes place in winter when trees have a lower moisture content.

Debarking and Bucking

Upon arriving at the mill, a giant mobile unloader grabs the entire truckload of trees and stacks it into long piles called log decks. These log decks are periodically sprayed with water to prevent drying out and shrinking.

Logs are then picked up from the log deck and placed on a chain conveyor that brings them into the mill. In some cases, the logs are “debarked,” meaning the outer bark of the log is removed with either sharp-toothed grinding wheels or a high-pressure water jet. This bark is pulverized and used to fuel the mill’s furnaces or sold as garden mulch.

As the logs make their way into the mill on a chain conveyor, a large circular saw called a bucking saw cuts them into predetermined lengths.

Breaking Down

Larger logs (2’-3’ in diameter) are broken down into smaller pieces using a large vertical bandsaw called a head rig saw. A computer recommends a cutting pattern to maximize the number of lumber pieces obtainable from the log. In general, thinner pieces are cut from the outer portion where there are fewer knots, and thicker pieces for dimension lumber are cut next. The center of the log yields stock for heavy timber pieces.

Bandsawing

The large cut pieces from the head rig saw, are laid flat, and moved by chain conveyor to a series of bandsaws where they are cut to the required widths, and the outside edges are trimmed square. The smaller diameter logs are fed through a series of bandsaws that cut them into 1”, 2”, or 4” thick pieces in one pass. Smaller pieces that don’t need further cutting may pass through a chipper which further grinds the uneven edges square.

Drying or Seasoning

The cut and trimmed pieces of lumber are then moved to an area to be dried or “seasoned.” When a tree is felled, it still contains between 40% to 50% water content. Seasoning is the process of removing excess water or moisture content. It prevents decay by allowing the wood to shrink as it dries out. As a result, the wood is less likely to warp or deform.

Timbers, because of their large dimensions, are difficult to thoroughly dry and are generally sold wet or “green.” Other lumber may be air dried or kiln dried, depending on the required moisture content of the finished piece. Air-dried lumber, which contains about 20% moisture, is stacked in a covered area with spacers between each piece to allow air to circulate.

Kiln-dried lumber is stacked in an enclosed area where 110-180°F (44-82°C) heated air is circulated through the stacks. Kiln-dried woods, which contain less than 15% moisture, are often specified for interior floors, molding, and doors which require minimal shrinkage.

Planing

The dried pieces of lumber are passed through planers, where rotating cutting heads trim the pieces to their final dimensions, smooth all four surfaces, and round the edges.

Grade Stamping and Banding

Each piece of lumber is visually or mechanically inspected and graded according to the number and location of knots, cracks, and natural marks. The grade is stamped on each piece, along with information about the moisture content, and a mill identification number. The lumber is then bundled according to the type of wood, grade, and moisture content—and the bundle is secured with steel bands. The bundles are loaded on a truck or train and shipped to a lumber yard for resale to customers.

Reforestation and Sustainability

America’s forests provide a rich habitat for wildlife, diverse plant and animal communities, clean water, beautiful scenery, and recreational opportunities. But natural catastrophes, excessive cutting, fire, insects, and historical farming practices require that we protect this valuable resource.

The roots of forestry regulation and preservation date back to 1876 when Congress requested that the Department of Agriculture assess the state of the forests in the United States. Today, the USDA Forest Service’s mission is to sustain the health, diversity, and productivity of the nation’s forests and grasslands to meet the needs of present and future generations. One of its top priorities is managing growth through reforestation programs like those created by the Knutson-Vandenberg Act of 1930. This act established forest tree nurseries and required timber sale purchasers to make deposits to cover reforestation costs and related work within timber sale areas.

Responsible wood flooring companies understand the delicate balance between man and the environment. Be sure to ask about certifications and their commitment to sustainability before choosing any manufacturer, product, installer, or a wood flooring professional.