Hardness

How well will your specified wood floor resist the indentation of the dreaded high heel?

Woodwright has always taken a very educational approach when assisting our valued Interior Designers and commercial Architects with selecting wood flooring for their projects.

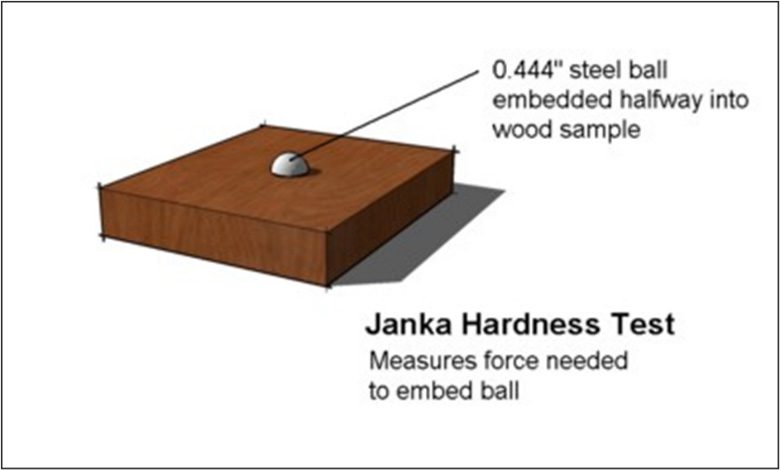

Wood’s density or hardness is measured with a Janka test which involves embedding a .444 inch steel ball exactly half its diameter into the wood.

Things to consider when it comes to pressure that can cause a dent.

- An Elephant exerts 50-100 PSI of pressure because the weight is distributed.

- Conversely, a stiletto heel can apply 2,000-3000 PSI of pressure which will commonly dent wood floors.

- An exposed high heel nail head – 8000 PSI. Ouch, that will leave a mark!

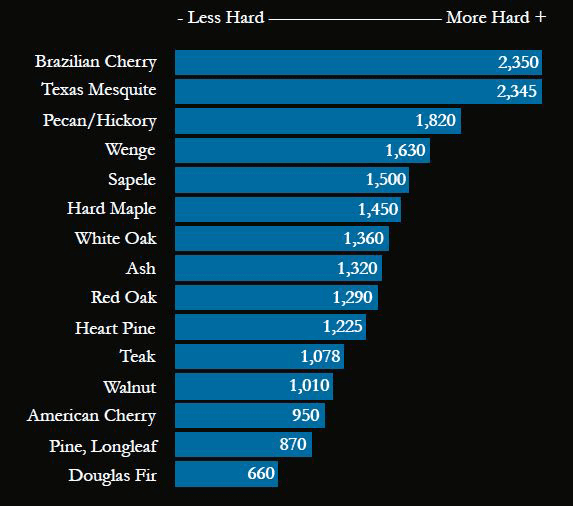

Using the Janka Hardness chart when selecting your wood floor is one of the best ways to determine a species ability to withstand denting due to pressure from a stiletto heel, the tip of a small chair leg, a rock stuck in the sole of a shoe, etc. We encourage our customers to select a specie that is appropriate for their build environment based on the clients’ expectations of wear.

Walnut floor in a restaurant/bar.

An important consideration when remodeling restaurant spaces is selecting the right wood flooring. This is crucial to ensure durability and longevity, especially in high-traffic commercial areas. Walnut, while visually appealing, may not be the best choice for commercial floors due to its softer grain structure and lower Janka hardness rating of 1010.

In commercial settings, it’s advisable to opt for harder wood species like Oak or Pecan that offer better resistance to wear and tear. These species are known for their durability and are often preferred for commercial flooring due to their higher Janka hardness ratings. Additionally, incorporating texture and a low-sheen finish can help diffuse light and minimize reflections, adding to the overall wearability and maintenance of the floor.

Consulting with Woodwright representatives for expert guidance on selecting the most suitable wood species, finish, and texture for your commercial space can help ensure that your wood floor not only looks great but also stands up to the demands of high-traffic environments.

Stability

Each species of wood flooring is unique. They not only vary in aesthetic, but in hardness and dimensional stability.

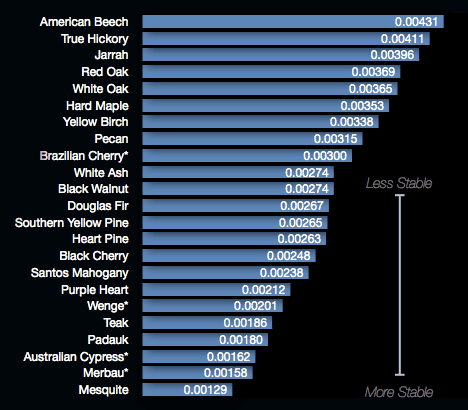

While the hardness of a particular wood gives us insight into its dent resistance; it’s the dimensional stability of the specie that references how it will “move” based on the environment it is installed in.

Wood is a product of nature grown in a factory called The Forest, using a renewable energy source called The Sun. You can’t get much more sustainable than that!

It’s also a hygroscopic material, which means that it will swell and shrink as it absorbs and loses moisture. The dimension change coefficient on this chart can be used to calculate expected expansion and/or contraction in various wood species.

The key environmental factors that affect wood floorings stability are the temperature and RH (relative humidity) of the surrounding air.

Other elements that affect the amount of dimensional stability within every unique plank.

- Specie selection

- Cut and grain configuration of the wood

- Board Width – Wider planks are inherently less stable.

- The degree of fluctuation to the conditions of the space.

To minimize the potential for this seasonal movement it is critical to maintain consistent humidity and temp levels year-round. This is best accomplished through the use humidification or dehumidification systems.

Just like humans wood flooring has a comfort level, too.

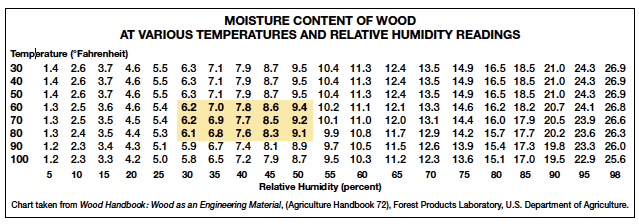

Wood flooring performs best when the environment in the space is controlled to stay within a relative humidity range of 30 to 50 percent and a temperature range 60 to 80 degrees Fahrenheit.

Ironically, that’s about the same comfort range most humans enjoy.

The chart below illustrates the likely moisture content of wood based on a combination of temperature and humidity in its environment. Note that the shaded area shows an equilibrium moisture content (EMC) of 6 to 9 percent, which happens to coincide with the range which most hardwood flooring is manufactured. Wood can experience some movement in this 6 to 9 percent range, however much of the wood’s expansion and shrinkage happen when the EMC is outside that range.

Having a better understanding of how relative humidity (RH) impacts wood movement is important to avoid wood flooring issues and installation failures.

Acclimation is an important step in managing how RH affects wood. Proper climatization is used to bring wood to the moisture content that coincides with the anticipated in-use conditions of the space in which it will live. This process is known as finding the equilibrium moisture content (EMC) of the wood.

For example, a dry climate such as Utah averages between 4 to 7 percent moisture content, while a humid or wet area like the Gulf Coast averages between 11 to 13 percent moisture content.

North Texas averages between 6 to 9 percent MC. Sort of a sweet spot!

These dramatic variances of relative humidity, coupled with the typical seasonal fluctuations, directly affect the moisture content at which wood flooring will acclimate to its surroundings. The goal is to identify where the wood will reside and install the flooring at a moisture content as close to final in-use conditions as possible.

No matter where the project is located, or which wood flooring product you are considering, following these simple rules of science can help you avoid most wood floor challenges related to moisture.

For more information on this subject or guidance on selecting the right specie for your project, contact our sales staff anytime or visit the find your rep page.