Architects & Designers

Real Wood Expertise… Rooted in Creativity.

Woodwright’s custom manufacturing capabilities provide architects and designers unlimited bespoke options to create the perfect solution for their client’s space. Whether your project involves floors, walls, ceilings, or stairs, we’ll help you curate the perfect 4D experience.

Contact your Local Woodwright

Architect + Design Representative

Request a project-specific

design consultation

Sustainability Initiatives

At Woodwright, we appreciate and understand the delicate balance between humans and the environment. At some point, almost every commercial architect or designer will find themselves searching for green building materials to meet the certification criteria for LEED, WELL, Living Building Challenge, or other sustainable projects. This search can become daunting with limited product choices available to meet their design intent.

Over 12 years ago, we began our own sustainability journey. Today, we are proud of and committed to manufacturing the vast majority of our tailor made products with the following compliancies:

FSC Certification -Solid and Engineered Products (2009)

Most every specie available with some level of FSC Certification except for Texas Mesquite, Post Oak, and most exotics

FloorScore Certification -Engineered Products (2016)

Most of our engineered products including many unfinished, shop and site finished wood floors

Health Product Declaration (HPD v2.3) - LEED v.4 Compliant (2017)

Expanded in 2020 to encompass almost every pre-finished, engineered, and solid product we can make

No added Urea Formaldehyde (NAUF) or Low emitting (ULEF)

VOC Complaint stains and finishes can be used on site finished floors

The Volatile Organic Compounds (VOC’s) limits do not apply to pre-finished floors

We are confident these sustainable efforts, coupled with our 100% custom capabilities, are a great benefit to design teams hunting for sustainable solutions. Questions regarding our sustainability initiatives? We’re happy to help!

What Makes Woodwright Different

The reality is most manufacturers are hoping you will fit their line into your project. At Woodwright, we take a different approach. As a 100% custom company with no running line products, colors, or SKU’s, we revolve our entire company’s capabilities and experience around your project. Bespoke, tailor made, custom – whatever you want to call it – this process doesn’t have to be costly or time consuming, it’s simply what we do every single day.

This preferred method of going to market is also supported by our truly educational approach. We don’t like to say, “no,” when it comes to our clients’ choices of specie, cut, color, or finish. However, we do love to keep them out of trouble when it comes to project appropriate selections. It’s what we do best!

Specie Selection

As the basis of design, choosing the perfect specie type sets the tone for your entire project.

White Oak

The most popular specie used in commercial wood flooring, few hardwoods are as versatile as White Oak. Known for its elegance and beauty in both traditional or contemporary settings This timeless American favorite has graced exquisite floors throughout the world and is prized for its variety of grain offerings and durability. It is an excellent flooring material that will allow for a variety of design options.

White Oak features a distinctive closed grain pattern that defines the specie with color that ranges from light, honey colored sapwood to rich golden-brown heartwood. White Oak is truly beautiful with a clear finish or can be stained to enhance its unique appearance. Beyond its surface beauty, White Oak is one of the most stable and durable of all the Oaks and is a floor that will last a lifetime.

Cuts:

- Plain Sawn

- Rift & Quartered

- Rift Sawn

- Live Sawn

Hardness Rating: 1360

Select Grade

- The most Uniform and Clearest of Standard Grades

- Nearly Free of Knots

- Limited Pin Knots and Character Markings

- Golden Brown Heartwood with Limited Lighter Sapwood

Light Rustic Grade

- Moderate amount of Knots and Character Markings

- Mix of Golden-Brown Heartwood with Lighter Sapwood

- Minimal amount of sound splits or cracks

- Light Rustic Grade requires filling

Rustic Grade

- Unlimited amount of Knots and Character Markings

- Mix of Golden-Brown Heartwood with Lighter Sapwood

- Minimal amount of sound splits or cracks

- Rustic/Character Grade requires filling

Hickory/Pecan

Often referred to as a Calico floor, the bold characteristics and natural color variations of Hickory/Pecan attract significant attention in any environment.

As one of the hardest North American species, Hickory/Pecan is one of the most popular and durable species selected for wood flooring, walls and stairs. The high contrast between heartwood and sapwood creates a floor that commands attention in any application.

Hickory/Pecan features distinct characteristics such as inconsistent character marks, cathedrals, and grain patterns that make this hardwood very desirable.The bold calico colors make a statement, especially when a clear finish is used, however that can be subdued with most stain colors. Colors range from white sapwood to dark reddish-brown heartwood.

Cuts:

- Plain Sawn

Hardness Rating: 1820

Select Grade

- The most consistent and premium of the standard grades

- Nearly free of Knots

- Limited Pin Knots, twig knots, bird pecks and mineral streaks

- Unlimited mix of Reddish-Brown Heartwood and Light Sapwood

Light Rustic Grade

- Moderate amount of Knots and Character Markings

- Unlimited mix of Reddish-Brown Heartwood and Light Sapwood

- Minimal amount of sound splits or cracks

- Light Rustic Grade requires filling

Rustic Grade

- Unlimited amount of Knots and Character Markings

- Unlimited mix of Reddish-Brown Heartwood and Light Sapwood

- Limited amount of sound splits or cracks

- Rustic/Character Grade requires filling

Walnut

Rich and luxurious, Walnut is a stunning addition to any environment. American Walnut has long been prized by furniture and cabinetmakers for its dark coloration, rich tones, fine smooth finish, and lustrous depth. It’s coloration is a harmonious blend of sandy brown to dark chocolate, which light sapwood streaks.

Walnut is a rather dimensionally stable material with low expansion and contraction characteristics. It carries a Janka Hardness Rating of 1010 making it one of the softer species typically used for wood floors. Woodwright does not recommend Walnut in heavy traffic environments as it is more susceptible to high heel dents than most other species. All Walnut has been traditionally steamed to minimize the harsh contrast of the inherent white sapwood.

Note: Woodwright also makes an Old Growth Texas Walnut that is non-steamed with deep inherent rich reddish tones. Just contact you’re A&D consultant for more information.

Cuts:

- Plain Sawn

- Quartered (Lineal Grain)

Hardness Rating: 1010

Learn More

Select Grade

- The most Consistent and Premium of Standard Grades

- Nearly Free of Knots

- Limited Pin Knots, Twig Knots, and Burl

- Minimum 80% Darker Heartwood

- Maximum 20% Light Sapwood

- Clear Grade available upon request to minimize sapwood

Light Rustic Grade

- Moderate amount of Knots and Character Markings

- Minimum 75% Darker Heartwood

- Maximum 25% Light Sapwood

- Minimal amount of sound splits or cracks

- Light Rustic Grade requires filling

Rustic Grade

- Unlimited Knots and Character Markings

- Minimum 70% Darker Heartwood

- Maximum 30% Light Sapwood

- Limited sound splits or cracks

- Rustic Grade requires filling

Red Oak

Red Oak is the dominate specie leader used in residential hardwood flooring. Beautiful, bold grain patterns and subtle, reddish-golden coloration makes Red Oak one of the most popular choices for flooring in the country. It’s harvested from the forests in the Northern and Appalachian regions of the United States known for producing Red Oak with the best color and texture.

Red Oak features a striking, open grain pattern that enhances cathedrals and provides a variety of high-contrast design possibilities. Natural to pastel stain colors on Red Oak can exhibit pink hues which may not be desirable, yet its open pores take a stain quite well, offering the ability to create dramatic wood finishes using a variety of unusual coloration techniques.

Cuts:

- Plain Sawn

- Rift & Quartered

- Rift Sawn

Hardness Rating: 1290

Select Grade

- The most Consistent and Premium of Standard Grades

- Nearly Free of Knots

- Limited Pin Knots and Character Markings

- Pinkish Red Heartwood with Limited Lighter Sapwood

Light Rustic Grade

- Moderate amounts of Knots and Character Markings

- Pinkish Red Heartwood with Limited Lighter Sapwood

- Minimal amount of sound splits or cracks

- Light Rustic Grade requires filling

Rustic Grade

- Unlimited amount of Knots and Character Markings

- Pinkish Red Heartwood with Limited Lighter Sapwood

- Minimal amount of sound splits or cracks

- Rustic/Character Grade requires filling

European Oak

European Oak is highly prized for its beautiful natural taupe tone, unique grain pattern produced by the Live Sawn cutting technique and its versatility of finishing processes. Because European Oak has a higher tannin content than American, it can be stained easier and with more consistency than American Oak.

Due to European oak being live sawn it typically comes in wider widths and even longer lengths. It tends to be stronger and expands and contracts less. It’s no wonder the popularity of European Oak has taken off in recent years.

Cuts:

- Live Sawn

Hardness Rating: 1360

Prime Grade

- Most Consistent and the cleanest of the Grades

- Limited Pin Knots and Character Markings

- Relatively uniform grey to taupe coloration with minimal Sapwood

Light Rustic Grade

- Moderate amounts of Knots and Character Markings

- Moderate color variation allowed between heartwood and sapwood.

- Minimal amount of sound splits or cracks

- Light Rustic Grade requires filling

Rustic Grade

- Unlimited amount of Knots and Character Markings

- Moderate color variation allowed between heartwood and sapwood.

- Moderate amount of sound splits or cracks

- Rustic/Character Grade requires filling

Texas Mesquite

Texas Mesquite is a red toned wood with moderate color variation and large amounts of grain variation. It is extremely hard with a Janka Rating of 2345 and literally one of the most stable woods used in the construction industry.

Woodwright developed our Multi Piece Face (MPF) product purposefully to better utilize this exquisite natural resource. One consistent grade now offers a better price point and reduced lead times. Our engineered planks are produced in 5’- 8’ long boards, much longer than the 9” to 48” offerings found in most solid Mesquite flooring, making it faster to install. The 4mm face lamella is made from multiple face pcs ranging from 9” – 48” long.

Cuts:

- Plain Sawn

Hardness Rating: 2345

Mill Run Grade (#2 & Better)

- #2 & Better Mill-Run grade Texas Mesquite is inherently very rustic and utilizes the entire tree. All structurally sound defects are incorporated into this grade and product.

- Unlimited amount of Knots, sound splits, cracks and Character Markings

- Moderate color variation

- No Sapwood allowed in Woodwrights Mesquite

- Character marks are filled with colored epoxy (typically black)

Texas Post Oak

Very few species rival the lasting impression made by Texas Post Oak. With every grain swirl, knot, beige streak and darker speckle Post Oak tells its own story in great detail. 100% locally sourced and manufactured in a millrun grade that is chock full of character.

Texas Post Oak is a salvaged wood mainly found in the Brazos Valley of Texas. Its distinction comes from its inherent beauty found in the naturally occurring color variations and less pronounced grain pattern. It is very different than any other Oak.

Cuts:

- Live Sawn

Hardness Rating: 1360

Rustic/Mill Run Grade

- Mill Run means utilizing the entire log for the best yield

- Unlimited amount of Knots, sound splits, cracks and Character Markings

- Moderate color variation with sapwood allowed

- Mill run Grade requires filling

Maple

Eastern Hard Maple is traditional and durable, well suited for wood floors Maple has dense closed grain making it a challenge to get deep stain penetration. One of the hardest and most durable wood flooring options available, it is most often used with simply a clear finish. Known for its light and bright appearance and high contrast coloring, ranging from the nearly uniform white of First Grade to the mix of white and medium reddish-brown tones of Second Grade and Rustic. Each of these grades have a drastically different appearance from the other and offers a wide range of design possibilities.

Hard Maple flooring has a long tradition being used in Gym floors as well as commercial applications where strength and durability are important. Not recommended for dry climates or over radiant heat. Maple is rather light sensitive and typically ambers with exposure to natural light.

Cuts:

- Plain Sawn

- Quartered (lineal grain)

Hardness Rating: 1450

Select Grade

- The most Consistent and Premium of Standard Grades

- Nearly all White Sapwood

- Nearly Free of Knots

- Limited Pin Knots and Mineral Streaks

- Clear Grade available upon request

Light Rustic Grade

- Moderate amount of Knots and Character Markings

- Unlimited Mix of White Sapwood and Reddish-Brown Heartwood

- Minimal amount of sound splits or cracks

- Second Grade may require filling

Rustic Grade

- Unlimited amount of Knots and Character Markings

- Unlimited Mix of White Sapwood and Reddish-Brown Heartwood

- Minimal amount of sound splits or cracks

- Rustic/Character Grade requires filling

Sapele

(Other exotic species available such as Wenge and Zebrawood)

A rich lustrous exotic hardwood Native to tropical Africa, also referred to as West African Mahogany. Sapele is a medium textured and moderately dense exotic hardwood that is excellent for wood flooring applications.

It features golden to dark reddish-brown coloring that is often more consistent than that of other Mahogany species. Sapele features a fine interlocking grain that is sometimes wavy, creating a uniform texture with beautiful natural luster.

Cuts:

- Mixed Grain – Mix of Plain (Cathedrals) and Vertical Grains

- Vertical Grain (Ribbon Striped) – Mostly Vertical Grain with Developing Ribbon

Hardness Rating: 1500

Prime Import Quality Grade

- The most Consistent and Premium of Standard Grades

- Golden to Dark Reddish-Brown Color

- Free of Knots and Sapwood

- Limited Pin Knots and Character Markings

- Medium Texture and Moderately Hard

Cuts of Wood

Woodwrights Custom-Made Edge Grain Material

It all started with Architects requesting thicker wood treads. Any solid wood tread over 1-3/4” thick becomes risky and problematic due to stability issues. The increased waste factor in thicker lumber also has significant cost implications. Woodwright began using their RF (radio frequency) glue machine to produce thicker treads using a butcher block technique. As creative solutions emerged from these efforts Woodwright began slicing lamella’s (wear layers) from these tread blanks and our edge grain engineered flooring was born. Perfect for floors, walls, stairs and tiered seating where a unique lineal grain fits the design intent.

Texture

The inherent beauty of wood is most often appreciated when it is sanded smooth and expertly finished, however, its beauty can also be enhanced through the addition of various surface textures. Woodwright’s handcrafted products are available with many aesthetically pleasing textures that often increase the wearability of a wood floor.

Woodwrights Signature Double Hand Scraped

Over a century ago, there was no ability to hone wood floors perfectly flat. The method used then was to cross-scrape the floor in order to first remove the highs and lows, then scrape every plank a second time, this time with the grain, to smooth it out. This technique was used to create the smoothest floor possible, yet the inherent gentle rolling texture that remained is what Woodwright artisans have been providing for over 35 years. While it may be a detailed process, it creates an authentic Old-World appearance that garnishes praise from our most discriminating clients. Case in point: The Old Parkland campus in Dallas boasts a large quantity of this specialty texture.

Color

Woodwright offers infinite color possibilities. Here, you are only limited by your imagination. For many companies, a “custom made sample” might be a hassle, but for the experts at Woodwright, it’s exactly what our day entails. Our creative sample department mixes unique new colors in our lab regularly, since most every sample they create is for a current or potential project.

No longer do you have to settle for a stain color or finish that’s just “close enough.” Simply discuss your sample needs with our Architect + Design consultants, or even provide us with something to match, like a laminate chip, paint chip, or fabric swatch.

Our custom sampling process typically takes 10-14 working days. However, if your needs are more urgent, we have hundreds of pre-made sample options in our Dallas showroom that we are happy to share. Our collection of showroom samples are organically updated thanks to our collaboration with top interior designers.

Finish

There are many wood floor finish options available in today’s market. Woodwright’s approach is to use what is in the client’s best interest, with a balance between durability and maintenance requirements. Learn more about selecting the correct finish here.

Common misconception between wood stain and wood finish

Wood stain simply refers to an element of the desired color, typically a liquid, that is applied to the wood, dying it a particular color. It offers no real protective properties as it penetrates into the wood grain. The actual top coat finish is what provides a shield against dirt and debris.

1. Urethane

Whether site-finished or shop-applied (pre-finished), urethane finishes are the most popular and most durable. This is especially true in commercial projects where ease of maintenance coupled with superior durability are generally the desired attributes.

The most common pre-finished floors in the marketplace today have an Aluminum Oxide (urethane) finish, making them extremely scratch-resistant and durable. However, because the finish is so hard, they can be difficult to re-coat.

With site finished floors the stain and top coats are applied in the field after installation and sanding. In this case we recommend two coats of water-based urethane which is quite sufficient. Perhaps not as durable as Aluminum Oxide but far easier to resand and finish.

- Urethane finished floors look the best the day they are installed. Over time, as they show signs of wear they may need to be recoated or refinished. This is a necessary step to increase the overall lifecycle of the wood floor.

- Damage to a urethane floor is easily identifiable by the white scratches on the finish (see image). Since you are walking on the top coat finish rather than the wood, more often than not, the damage stays contained to the finish. Fixing the finish is fairly simple: just remove all furniture from the space and apply a fresh uniform coat of finish.

- We recommend utilizing a Matte or Satin sheen to minimize the reflective nature of a top coat.

- Typical Maintenance on a urethane finished floor is simply dry mopping, vacuuming and cleaning using only recommended cleaners. We do not recommend using any hardwood polish or products containing waxes, oils or ammonia.

2. Oil Finishes

With a low sheen and more natural aesthetic, oil finished floors are very desirable in today’s marketplace, especially in residential projects. While not as durable as a urethane finish, they do offer greater flexibility in repairing any damage.

On an oil-finished floor, you are walking on the wood surface versus a protective coating like on most urethanes-finished floors. When scratches occur on oiled floors, you can buff and blend them away very easily without removing the furnishings. While this may be an advantage it comes at a price. Diligent and proper maintenance is the key to protecting any oil finished floor.

The two main types of oil commonly used on wood floors include:

- European Hardwax Oil – This matte sheen penetrating oil offers the advantages listed above with one huge caveat… required maintenance! Very popular, especially in Residential projects where often the maintenance can be monitored and performed properly. In commercial projects, however, the reality is that the intense maintenance requirements will likely not be performs properly or diligently and the appearance of the floor will go downhill quickly. Based on Woodwright extensive experience in commercial wood floors we seldom recommend Hardwax Oil for even light traffic floors in commercial spaces.

- Tung Oil – Woodwright uses Waterlox Tung Oil quite frequently when it is appropriate for the application. It applies and maintains similar to Urethane yet offers the flexibility of repairs like an oil, or even an old-world wax floor. It’s perfect for restaurants, dark floors, and textured floors.

Contact your Local Woodwright

Architect + Design Representative

Request a project-specific

design consultation

Frequently Asked Questions

How do I specify a Woodwright product?

You can order a sample from our website or Material Bank – these are the same samples found in our sample boxes located in many A&D libraries. Or, you can contact your Architecture & Design representative, who will be happy to assist you.

How do I request a sample box for our library?

You can do this through your Architect & Design representative, which you can contact contact a few ways: Through our Find Your Rep page, our Contact Us page, or by simply calling our office at 214-630-8811 and asking for an Architect & Design representative.

How do I find my specific representative to assist me with a project?

You can find them through Find Your Rep page on our website.

Does Woodwright have a line of standard products I can view online?

How does custom sampling work?

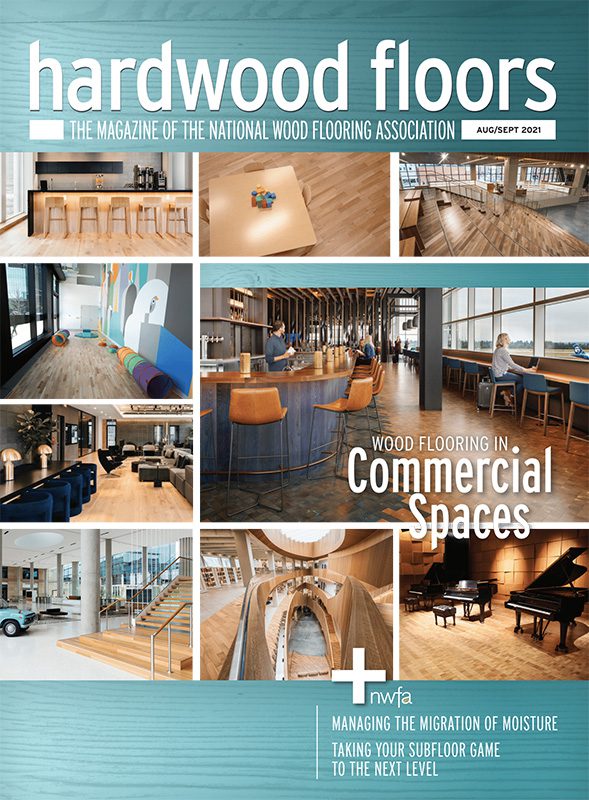

Does Woodwright offer CEU courses?

Yes, we offer several different CEU’s sponsored by the National Wood Flooring Association (NWFA). These can be scheduled with your Architect & Design Consultant through our Find Your Rep page. They can be taught virtually or in person depending on your location.