Medallions, inlays, parquet and more fun with lasers and CNC

In last month’s blog, we discussed trends in wood flooring, including medallions. Medallions evolved from the arts of parquetry and marquetry. Parquetry comes from the French word parquet meaning “a small compartment.” Parquetry is a geometric mosaic of wood pieces used for decorative effect in flooring. Today’s medallions and intricate wood inlay floors also borrow from the practice of marquetry (from the French marqueter, to variegate) which is the art and craft of applying pieces of veneer to a structure to form decorative patterns, designs, or pictures. Marquetry is often used in furniture and is usually very floral-based. Parquetry can also be used in furniture but is more geometry-based.

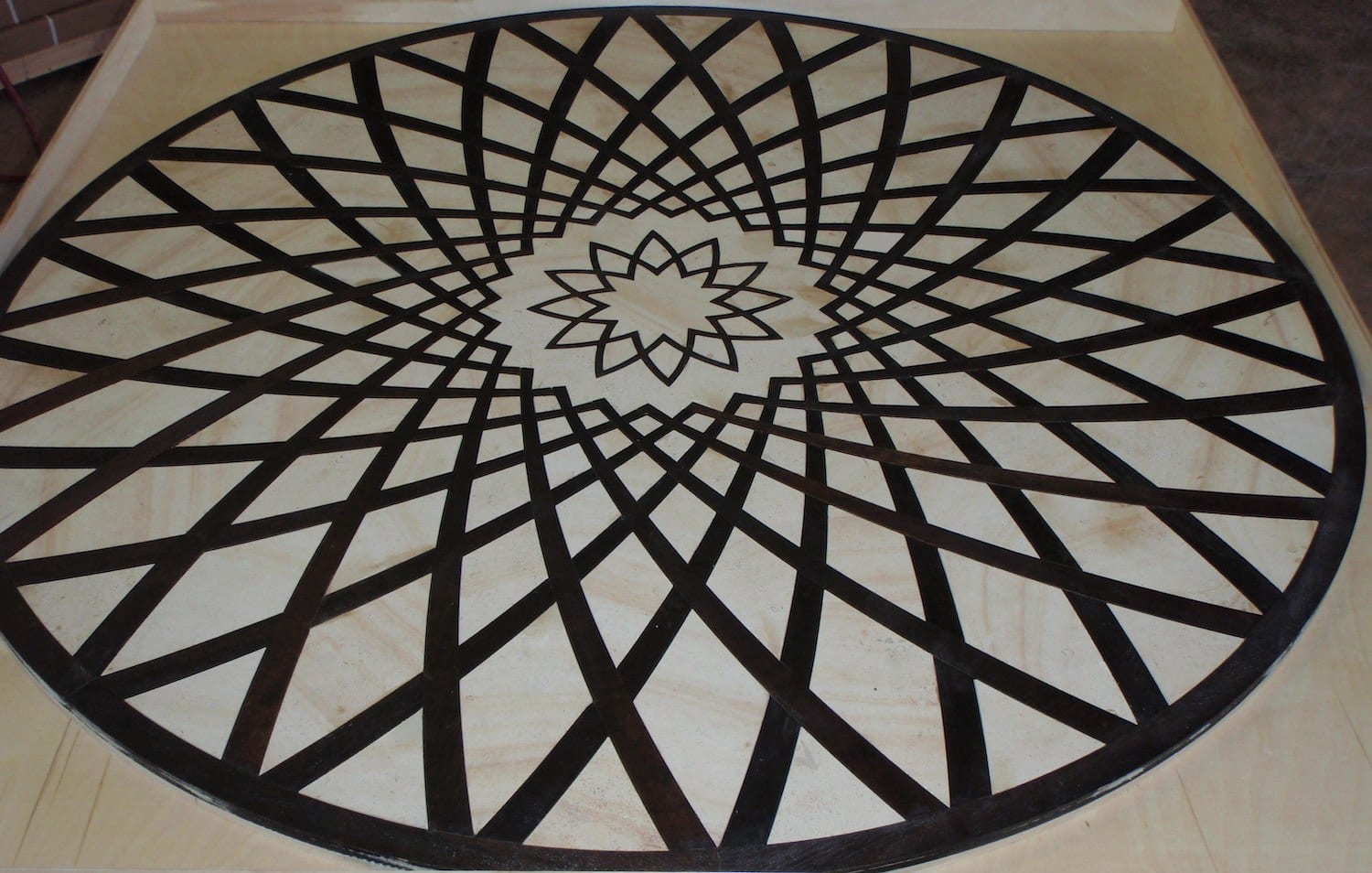

Now, back to wood flooring. A medallion is a geometric shape embedded into the floor, usually in a foyer or entryway, to add a distinctive look. It’s like a signature or work of art that is incorporated into the structure of your building. Medallions create a focal point, adding a bit of “wow factor” the minute a client or customer walks through your door.

Medallion designs can use anywhere from a few to hundreds of species pieces in numerous precise sizes and shapes. Most people are amazed at how complex and stunning medallion designs can be. They can be star-shaped, round, nautical-themed, patriotic, geometric, a family crest, company logo, etc. And they can include letters, words, and symbols.

In terms of size, a medallion can be designed to fit any room or setting, from a small stairway landing to a large ballroom or conference room. The largest one Woodwright ever created was 16 feet in diameter and was installed in a private debate room in Dallas. It featured Walnut, White Oak End Grain blocks, bronze inlay and Wenge (exotic hardwood) pieces.

What about color? With the large variety of woods and stains available today, just about any color, you can imagine can be reproduced. Also, just about any three-dimensional shape—a mountain, animal, facial profile, or building—can be replicated.

In 2014, Woodwright won the National Wood Flooring Association’s Best CNC/Laser Cut Wood Floor of the Year award for Dallas designer Emily Owens and her client who wanted a custom seal for the floor in his library. This project combined depth, dimension, and color in a striking and intricate design. You can read more about it here.

Creating a piece like the one pictured above required a combination of laser-cutting, CNC (Computer Numerical Control) wood bending, and hand tooling to get the desired effect and took approximately six months.

On the other end of the spectrum, a medallion can be a simple geometric pattern that adds visual interest to an otherwise average-looking floor.

What else can lasers do?

The short answer? Both and neither!

That’s because a CNC and laser-cutting machine are essentially the same machines. Both are controlled by computers and used (in this case) to cut wood – the difference is the depth of the wood and the details they’re suited for.

A CNC is more like a router. It can cut through up to 4” of solid wood and is best suited for creating rounded corners but can be used to make any shape when used for surface engraving. The operators use different bits to change the pattern or shape of the cuts.

A laser is perfect for engraving but is not capable of cutting to the same depth as a CNC. It’s great for creating sharp corners. Higher end machines do an excellent job of reproducing images onto pieces of wood, especially detailed faces, logos, landscapes, buildings or any other images with fine detail because it actually burns with a precision laser rather than simply cutting it like a knife.

Most of the projects you see pictured here used a combination of CNC and laser-cutting technology to get the image and effect the customer wanted. And that’s fine; because at Woodwright, we love a challenge!

Can a medallion be installed in an existing floor?

Well of course! In most cases, whether it’s new construction or renovation, medallions can be incorporated at the same time or after new flooring has been installed.

Sometimes, the medallion is created as an engineered material with a thick wear layer (approx. 4mm to 6mm thick) to match the thickness of the existing hardwood floor. Then a template is used to cut out a hole or space that perfectly fits the medallion. (This is probably the most nerve-wracking part for the artist who created the piece because the slightest mistake can ruin hours and hours of work.) After placing the medallion in the floor, the floor is sealed and refinished to look as if the seal was built right into the existing floor.

It’s important to understand that decorative floor medallions will rarely (if ever) blend seamlessly with surrounding hardwood flooring. Differences in color, grain, and texture may be due to wood age, species, treatment, and more. But these variations are what make floor medallions so lovely and dramatic.

What else can lasers do?

You can also add drama to a floor by creating a pattern, using a process similar to that used for creating medallions. These puzzle pieces can be laser cut in the shop then assembled into any pattern to fit any space or suit any taste.

Here are two more examples of how geometric shapes that can be assembled to create patterns or create the look of a three-dimensional floor with shape and color.

Woodwright’s architect + design consultants work with architects and designers from the initial design concept phase—including custom sampling and assistance with specifications—so we can help answer any questions, explore options, brainstorm with you, and help you imagine all the possibilities.

Here are two more examples of how geometric shapes that can be assembled to create patterns or create the look of a three-dimensional floor with shape and color.

Let us make your vision a reality.

Woodwright’s architect + design consultants work with architects and designers from the initial design concept phase—including custom sampling and assistance with specifications—so we can help answer any questions, explore options, brainstorm with you, and help you imagine all the possibilities.