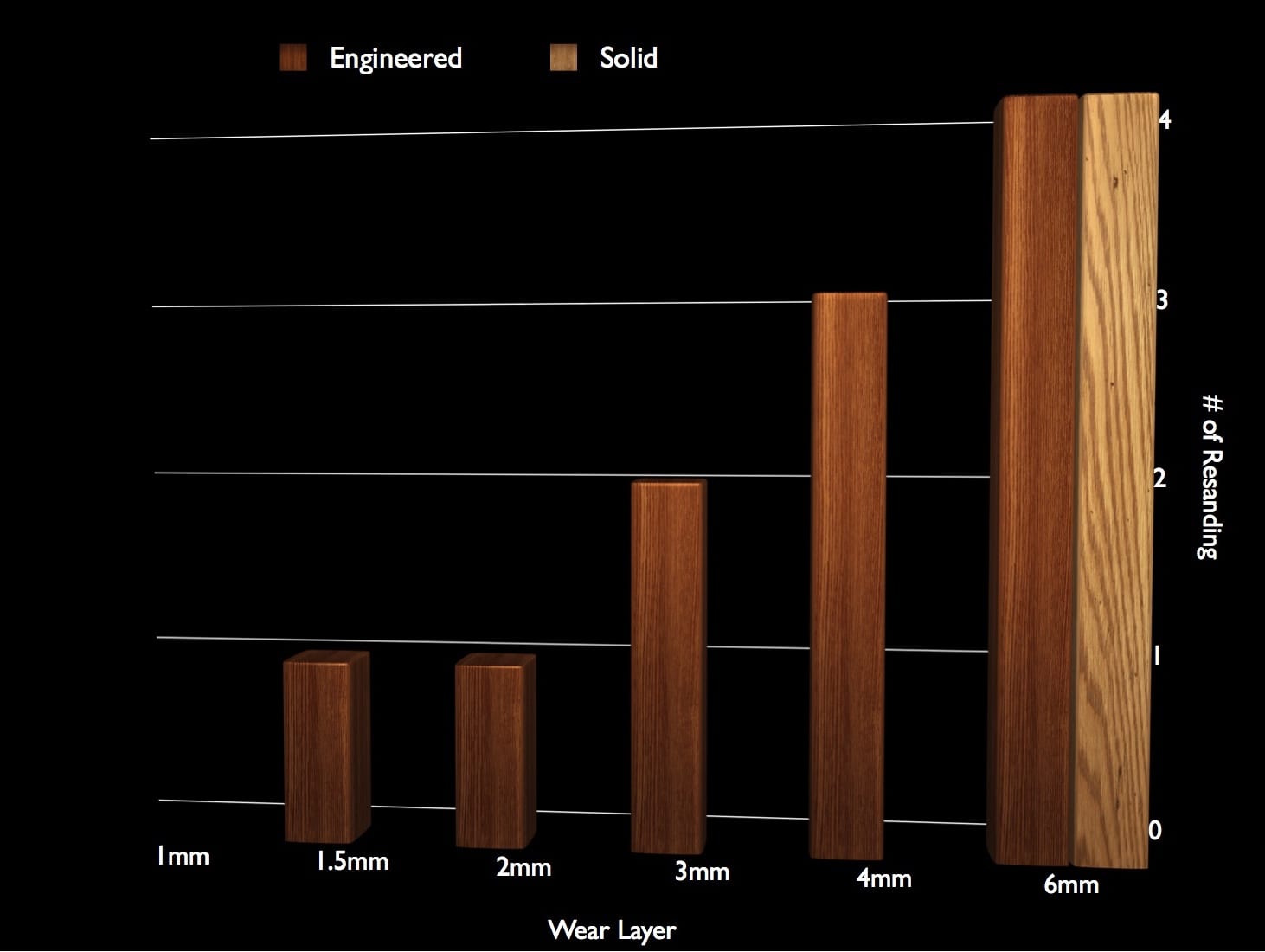

When we first get into the discussion of wear layer, we must define the term wear layer. Quite frankly it refers to the re-sandable wood surface above the tongue and groove on wood flooring. On 3/4″ solid wood floors, the wear layer is typically 6 millimeters (0.23622 inch). Depending on texture (yes, heavy texture does effect your future re-sandings), you can typically expect 4-5 re-sandings.

Now let us examine re-sandability of engineered wood floors. With so many types of engineered wood floors in the marketplace, we will start by defining what an engineered wood floor is and what it is not. First and foremost, it is not laminate! Laminate wood floors are essentially a “photograph” of wood grain glued to some type of backing material. In most cases it may be MDF or similar. In reality engineered wood floors are constructed of either a rotary cut or sawn piece of lumber that is glued to a structural backing. So why use engineered wood floors? First, they may be directly glued to the concrete slab. Secondly, if using a less stable specie (see chart), an engineered wood floor provides additional stability. When you select a Woodwright product, you get a sawn piece of lumber on a structurally sound backer. Yes folks, it is real wood! When it comes to thicknesses and wear layer of engineered wood floors, you face a wealth of options. Floor thicknesses may range form 3/8″ to 3/4″.

Our engineered wood floors typically come in 2 thicknesses. First, we offer a 5/8″ engineered wood floor with 4 millimeters (0.15748 inch) of wear layer. Again depending on texture, you can rely on 3-4 re-sandings. Our second engineered wood floor is 6 millimeters (0.23622 inch) of wear layer. This is apples to apples re-sandability as compared to solid wood flooring and you get the added stability if you are using less stable specie. See the image below for a chart on estimated re-sandings of wood floors with varying wear layers.

A lot of times we will receive the comment about engineered wood floors that the client does not want engineered because they do not like the edge treatment of glossy, pre-filled finish that dominates the marketplace today. You know what? You do not have to settle for that either. Woodwright’s engineered wood flooring can be installed, field sanded and finished to crate the seamless, site finish look so many clients crave. Our engineered wood floors are completely customizable so you do not have to settle.

Getting back on track, so why is wear layer important? Product life is the simple answer. Rather than having to replace or throw away a thinner wear product, you can sand and finish thicker wear layer product multiple times. In our next post, we will expand on the cost evaluation to demonstrate the long term value of selecting wood flooring with thicker wear layer.

Cheers till next time!